In industrial lifting and material handling, choosing the right crane can mean the difference between effortless productivity and constant frustration. Two common choices for workshop lifting equipment are the mobile workshop crane and the counter-balanced floor crane. While both tools are designed to help you lift heavy loads in a workshop or industrial setting, they differ significantly in design, maneuverability, versatility, and overall efficiency. In this article, we’ll explore why the counter-balanced floor crane, especially models with a no front legs design, offers distinct advantages over traditional mobile workshop cranes.

Understanding the Basics: What Is a Mobile Workshop Crane?

A typical mobile workshop crane, such as the SC1000C mobile workshop crane offered by i-Lift Equipment, is designed for general lifting duties in garages, workshops, and maintenance facilities. It features a sturdy frame, a telescopic jib with multiple capacity settings, a heavy-duty hydraulic ram, and a foldable design for storage when not in use.

These cranes are popular for tasks like lifting engines, machinery, and other heavy components. Their foldable design helps save space and makes them easy to store or transport on rolling casters.

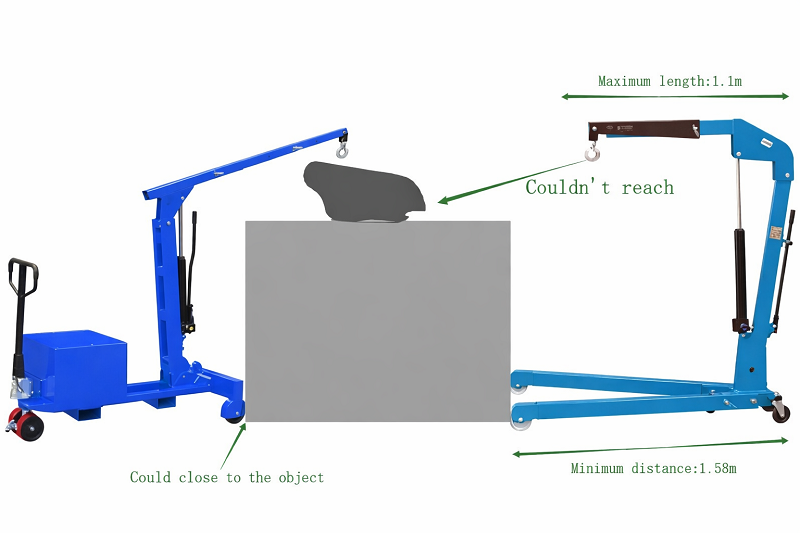

However, despite these strong core features, mobile workshop cranes have at least one limitation: support legs that extend forward beneath the working area. These legs are necessary to stabilise the crane during lifting but can obstruct access, reduce flexibility, and restrict use in tight spaces.

The Innovation: What Is a Counter-Balanced Floor Crane?

In contrast, counter-balanced floor cranes are specially engineered lifting machines that use strategically placed counterweights to balance the load instead of relying on forward-extending support legs.

By using counterweights behind the mast, these cranes can safely lift heavy loads while eliminating the need for front legs. This seemingly small design detail delivers a set of major practical advantages — especially in confined or complex workshop environments.

These cranes range from compact manual models to fully electric powered systems, but all share the defining feature of no front legs — unlocking greater access and operational flexibility.

1. Greater Access and Maneuverability

The most tangible advantage of a no front legs counter-balanced crane is unobstructed access to work areas. Traditional mobile workshop cranes must extend stabilising legs forward, which can block pathways or prevent the crane from getting close to walls, equipment, or vehicles. In contrast, counter-balanced cranes place weight at the rear, keeping the front clear.

This design means you can position the lifting arm right up against machinery or load without worrying about crane legs interfering. Whether you’re lifting a gearbox behind a machine or working in a narrow aisle, the absence of front legs means fewer limitations on where you can lift from.

2. Better Fit for Confined Spaces

Industrial facilities often deal with tight or congested workspaces — production lines, assembly stations, or workshop bays where every inch counts. The no front legs design significantly improves the crane’s ability to navigate in such environments.

Mobile workshop cranes, though mobile, can still be cumbersome when the forward-extending legs restrict how close you can get to the workpiece. Counter-balanced cranes eliminate that problem, enabling closer lifting and more fluid workflow.

3. Enhanced Safety Through Stability

Without a counter-balanced design, cranes rely on wide bases and forward-extending legs to remain stable during lifts. While effective, this approach has limitations, especially when lifting awkward or off-centre loads. Counter-balanced floor cranes use rear counterweights to balance the load, which provides stable lifting without front leg support.

This results in a stable center of gravity even when lifting heavy or unusual loads — reducing the risk of tipping or shifting during operation. In many industrial settings, safety isn’t just desirable; it’s mandatory.

4. Improved Efficiency, Productivity, and Workflow

A crane that can get closer to the object being lifted — without support legs getting in the way — inherently speeds up workflows. Whether you’re moving parts between stations, lifting heavy components for installation, or handling maintenance tasks, reducing obstacles on the shop floor saves time and effort.

Additionally, the mobility and compact footprint of counter-balanced cranes allow them to be used across multiple zones without requiring complex repositioning — meaning workers spend less time setting up and more time completing tasks.

5. Cost-Effectiveness Through Versatility

Though counter-balanced floor cranes like the ones listed above tend to have a higher upfront cost than basic mobile shop cranes, they often replace the need for additional lifting devices or workaround procedures. Their ability to perform lifting tasks in tight, complex spaces — without additional support rigs — makes them more cost-efficient in the long term.

Moreover, these cranes are designed for ease of operation and low maintenance, with intuitive controls and rugged construction that keeps long-term ownership costs manageable.

6. Real-World Applications and Industry Relevance

Counter-balanced floor cranes are widely used in industries that demand precision and flexibility — including automotive assembly, aerospace manufacturing, metal fabrication, logistics, and maintenance facilities. Their compact design and enhanced maneuverability make them indispensable in challenging industrial scenarios that typical mobile workshop cranes struggle with.

Final Thoughts: Choosing the Right Crane for Your Workshop

Both mobile workshop cranes and counter-balanced floor cranes have their place in material handling. Mobile workshop cranes like the SC1000C are excellent all-around options for lift-and-store tasks and general workshop use.

However, when your workflow requires tight-space access, advanced positioning, and minimal obstruction, the no front legs design of counter-balanced floor cranes clearly stands out. From improved safety and flexibility to productivity gains and long-term operational cost benefits, this innovative design isn’t just a feature — it’s a competitive advantage.

If you’re outfitting a workshop, industrial space, or maintenance facility where lifting precision and mobility matter, choosing a counter-balanced floor crane might be one of the best decisions you make this year.