Repetitive bending, lifting, and twisting are major causes of musculoskeletal disorders (MSDs) in warehouses, production facilities, and assembly lines. Every day, operators handle bins, baskets, and boxes filled with components — often hundreds or thousands of times per shift. Without ergonomic solutions, lower back pain, strains, and fatigue are inevitable.

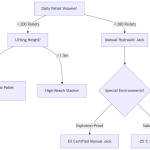

A pallet tilter like the LT10 Pallet Tilter provides a practical solution to protect workers while boosting efficiency.

The Hidden Risk: Repetitive Bending and Lifting

Workers picking parts from bins or tote boxes frequently bend forward, twist, or reach awkwardly. Even moderate loads, repeated daily, can lead to:

- Chronic lower back pain

- Shoulder and neck strain

- Rapid fatigue and reduced productivity

European safety guidelines emphasize that MSDs are preventable with ergonomic handling solutions. Investing in devices that reduce bending and awkward postures is critical for workplace safety.

How a Pallet Tilter Reduces Injuries

A pallet tilter tilts pallets or bins to an optimal working angle, allowing operators to maintain a neutral posture. The benefits include:

1. Reduce Bending and Twisting

Tilting the load brings items closer to the worker, eliminating the need for repeated bending and twisting. This reduces lower back stress.

2. Encourage Proper Posture

By keeping the spine aligned and minimizing awkward movements, workers can pick, sort, or pack parts without muscle strain.

3. Increase Productivity

Operators can access items more easily, improving picking speed and accuracy, while reducing fatigue over long shifts.

4. Handle Heavy Loads Safely

Even for loads up to 1000kg, a pallet tilter allows controlled tilting, minimizing the risk of injuries during handling or lifting.

LT10 Pallet Tilter: Protecting Workers and Improving Efficiency

The LT10 Pallet Tilter is designed for European warehouses, workshops, and production lines where repetitive picking or sorting occurs.

Key Features:

- Capacity:1000kg – supports heavy pallets and bins

- Tilting mechanism:adjustable to ergonomic working height

- Smooth operation:reduces physical effort and strain

- Robust construction:ideal for frequent use in industrial environments

Benefits:

- Minimizes repetitive bending injuries

- Improves workflow and productivity

- Easy integration into picking stations or assembly lines

- Supports compliance with European health and safety regulations

Practical Applications for European Warehouses

The LT10 Pallet Tilter is suitable for:

- Picking parts from tote bins or baskets

- Feeding components into production lines

- Loading/unloading pallets safely

- Manual assembly operations requiring repetitive picking

With the LT10, workers can focus on accuracy and efficiency while reducing back injuries.

Picking With vs Without a Pallet Tilter

| Feature | Without Pallet Tilter | With LT10 Pallet Tilter |

| Posture | Frequent bending/twisting | Neutral spine |

| Back Strain | High | Low |

| Fatigue | Rapid accumulation | Reduced |

| Picking Efficiency | Moderate | High |

| Safety | Risk of MSDs | Minimized |

Conclusion: Reduce MSDs and Boost Efficiency

Repetitive bending and lifting are leading causes of MSDs in European warehouses. By integrating a pallet tilter like the LT10 (1000kg):

- Lower back strain and fatigue are minimized

- Workers maintain proper posture

- Picking efficiency and safety improve significantly