Introduction of high lift truck

High lift truck is a new design with larger piston to offer you real 1000kg and 1500kg capacity. This series JL are manual high lift pallet jack and JE are electric high lift truck. It is very suitable as combined hand pallet truck and lift table. With the ergonomic warm handle, it is very simple and comfortable for you to operate. Besides, front support legs and adjustable stabilizers extended to the floor automatically with the rising of the fork, which can ensure the maximum stability and optimum braking. It can keep the same speed regardless of the truck with or without load.

This high lift pallet trucks can lift the pallets loading or unloading to the height you need. they can be used in various applications like factory, workshop, warehouse etc.

The manual high lift pallet truck has model: JL5210, JL6810, JL5215, JL6815;

The electric high lift pallet truck has model: JE5210, JE6810, JE5215, JE6815

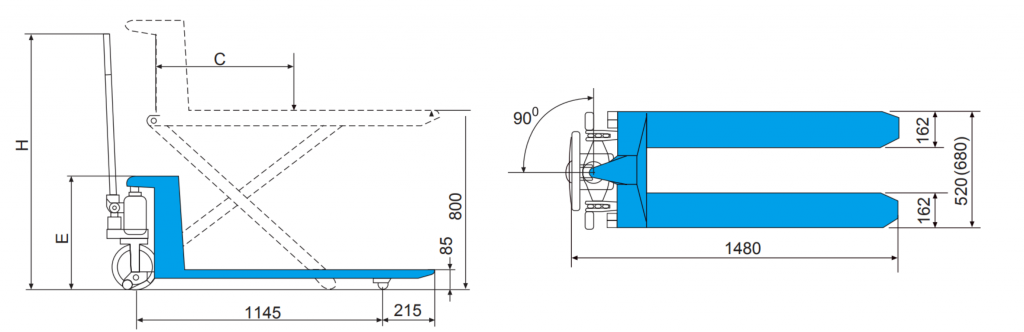

Manual high lift pallet truck JL series

We have this item in stock in France, if you are located in Europe, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

Specifications of manual high lift skid jack truck:

| i-lift No. | 1410601 | 1410603 | 1410605 | 1410607 | ||

| Model | JL5210 | JL6810 | JL5215 | JL6815 | ||

| Capacity | kg(lb.) | 1000(2200) | 1500(3300) | |||

| Fork height | mm(in.) | 85-800(3.3-31.5) | ||||

| Fork overall width | mm(in.) | 520(20.5) | 680(26.8) | 520(20.5) | 680(26.8) | |

| Fork length | mm(in.) | 1140(44.9) | 1140(44) | |||

| Dimension | C | mm(in.) | 600(23.6) | 600(23.6) | 560(22) | 560(22) |

| E | 530(20.9) | |||||

| H | 1250(49.2) | |||||

| Net weight | kg(lb.) | 105(231) | 112(246.4) | 118(259.6) | 125(275) | |

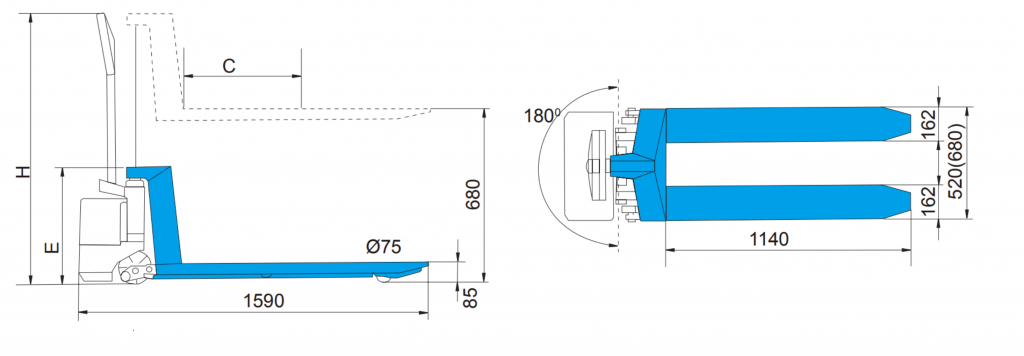

Electric high lift pallet truck JE series

Specifications of electric high lift pallet truck:

| i-lift No. | 1410602 | 1410604 | 1410606 | 1410608 | ||

| Model | JE5210 | JE6810 | JE5215 | JE6815 | ||

| Capacity | kg(lb.) | 1000(2200) | 1500(3300) | |||

| Fork height | mm(in.) | 85-800(3.3-31.5) | ||||

| Fork overall width | mm(in.) | 520(20.5) | 680(26.8) | 520(20.5) | 680(26.8) | |

| Fork length | mm(in.) | 1140(44.9) | 1140(44) | |||

| Dimension | C | mm(in.) | 600(23.6) | |||

| E | 530(20.9) | |||||

| H | 1250(49.2) | |||||

| Battery | (Ah/v) | 70/12 | ||||

| Battery Charger | (A/V) | 8/12 | ||||

| Net weight | kg(lb.) | 140(308) | 147(323.4) | 149(327.8) | 157(345.4) | |

- High quality oil cylinder: The integrally sealed hydraulic cylinder can effectively avoid the disadvantages of oil leakage, improve the safety performance of the whole vehicle, lift quickly and improve work efficiency.

- Comfortable handle: Ergonomic design, the outer layer is rubberized and non-slip, the operation feels comfortable, and the drop speed of the hand-pulled pressure relief heavy cargo is controllable, which improves the operation safety.

- Exquisite workmanship: The surface of the car body has been subjected to high temperature baking paint, electrostatic spraying, the surface is smooth and smooth, durable, beautiful and corrosion-resistant.

- Anti-pinch scissors: The scissors are designed with increased spacing and anti-clamping to prevent accidental clamping of other items. Thickened steel enhances the bearing capacity, making it safer and more durable.

Features of high lift trucks:

- Extremely easy.to pump and light make this unit very suitable as combined hand pallet truck and lift table

- Automatic descendng speed control by a uniquely hydraulic valve,the decending speed always keeps same regardless the truck with or without load. lt will prevent cargo damage from fast descending.

- Heavy duty design: 4mm steel plate fork frame and larger lift piston ensure the truck to reach rated capacity.

- Very suitable as combined hand pallet truck and lift table

- Front support legs and adjustable stabilizers extended to the floor automatically when the forks reach a height of 420mm, to ensure maximum stability and optimum braking.

- Conforms to EN1757-4.

Attention and Maintenance:

Do not overload;

Whether the ground conditions are allowed to be used;

Load the goods correctly;

Wear safety shoes and gloves when handling;

Please do a thorough operation check before each use;

Assembling the machine with the correct lifting technique;

Don't overlook the potential dangers that may exist during operation.

Proper maintenance will extend the life of the truck.

Check the oil, remove air and lubricate during maintenance.

Check the oil level every six months.

The newly injected oil to the rubber container should be 5mm below the liquid level, and the fork must be at the lowest position when adding oil.

When replacing the seal, air may enter the hydraulic system, place the joystick in the LOWER position, and then swing the handle a dozen times.

Lubricate the movable part with motor oil or oil.

Also pay attention to daily inspection and maintenance.

Inspection of the truck can reduce wear as much as possible.

Special attention should be paid to the wheel, axle, handle, fork, lift and lowering control.

Whenever work is completed, the fork should be unloaded and lowered to the lowest position.