When purchasing a 400kg capacity light stacker, many warehouse managers and logistics professionals face the same question:

Should I choose a manual light stacker or a semi-electric light stacker for my facility?

Selecting the right 400kg light stacker is critical for productivity, safety, and cost efficiency, especially in European warehouses, small distribution centers, and retail stockrooms with narrow aisles and confined spaces.

In this article, we’ll provide a detailed manual vs semi-electric light stacker comparison, helping you make an informed decision.

Manual vs Semi-Electric Light Stacker: Key Differences

Operation:

- Lift loads using a hand pump

- Move loads manually

Advantages: - Lowest initial purchase cost

- Zero emissions, no batteries required

- Minimal maintenance

- Easy operation, ideal for small teams

Best for: - Occasional lifting tasks

- Short travel distances

- Budget-conscious operations

- Small warehouses or offices

Considerations: - Operator exerts physical effort to move loads

- Slower lift cycles for frequent use

Semi-Electric 400kg Light Stacker

Operation:

- Electric lift mechanism powered by battery

- Manual push/pull for traveling

Advantages: - Reduced operator fatigue with electric lifting

- Faster lift cycles for repetitive tasks

- Ideal for multi-shift operations

- Compact enough for narrow aisles

Best for: - Frequent lifting and stacking

- Taller shelving and mezzanine storage

- Medium-sized warehouses and workshops

- Ergonomics-conscious environments

Considerations: - Higher purchase cost

- Requires battery maintenance

- Travel is still manual

Side-by-Side Comparison

| Feature | Manual 400kg Light Stacker | Semi-Electric 400kg Light Stacker |

| Lifting Mechanism | Manual hand pump | Electric lift |

| Travel | Manual | Manual |

| Operator Fatigue | Higher | Lower |

| Lifting Speed | Slower | Faster |

| Purchase Cost | Lower | Higher |

| Maintenance | Minimal | Battery care |

| Best Use | Occasional lifting | Frequent/repetitive lifting |

| Ideal Setting | Small warehouses / offices | Medium to large warehouses, multi-shift |

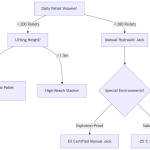

How to Choose the Right 400kg Light Stacker

Choose Manual If:

- Light workload and occasional lifting

- Short travel distances

- Cost-sensitive operations

- Limited staff or simple warehouse layout

Choose Semi-Electric If:

- Frequent lifting or repetitive stacking

- Taller racks and multi-level storage

- Ergonomics and operator safety are priorities

- Medium or large warehouse environment

Applications Where Light Stackers Outperform Forklifts

Light stackers excel in narrow aisle warehouses or compact spaces where traditional forklifts are impractical:

- Office material handling

- Mailroom handling

- Archive and document storage

- Retail stockrooms

- Laboratories and clean environments

- Small workshops

Keywords: narrow aisle warehouse equipment, compact warehouse handling solution, light duty stacker

Conclusion

For European warehouses, small workshops, and office storage, choosing the right 400kg light stacker can improve efficiency, reduce costs, and enhance workplace safety.

- Manual Light Stacker (SPJ 400kg):Cost-effective, low maintenance, ideal for occasional lifting.

- Semi-Electric Light Stacker (SEJ 400kg):Efficient, ergonomic, suitable for frequent lifting and taller storage.

Selecting the correct type depends on workload, frequency, and ergonomics needs.