Introduction

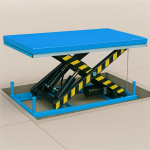

A custom stationary lift table plays a vital role in material handling, production lines, and warehouse operations. When customers require customized configurations, selecting the correct specifications is essential for safety, performance, and long-term durability.

Below are the five most important factors to consider when customizing a stationary lift table. Hopefully, this will help you buy the right product.

1. Load Capacity – The Most Critical Factor in Lift Table Customization

Load capacity is the foundation of every customized lift table design. It determines the structural strength, hydraulic cylinder setup, and motor power.

For example, the HW Series stationary lift table is ideal for lifting 1000 kg, 2000 kg, and 4000 kg loads commonly found in workshops and production lines. This series is engineered to provide stable lifting for medium to heavy-duty applications.

When confirming capacity, consider:

- Maximum load weight

- Whether the load is evenly distributed

- Whether pallet trucks or trolleys roll onto the platform

Selecting the correct rated capacity ensures safe lifting and reduces mechanical wear.

2. Lifting Height & Lowered Height – Ensuring Workflow Compatibility

The lifting height and minimum closed height determine the scissor structure, cylinder stroke, and the number of scissor stages (single, double, or triple scissor lift).

Consider:

- Required maximum height to match conveyors, assembly lines, or truck beds

- Minimum height needed for loading

- Whether low-profile design or pit installation is required

If the minimum height must be extremely low, a pit-mounted lift table is often the best solution for creating a fully flush working surface.

The HW Series is typically installed in a pit. After being embedded in the ground, the closed height becomes flush with the floor, allowing pallet trucks and manual trolleys to be easily rolled onto the platform. Although the specification sheet shows a maximum lifting height of 1000–1400 mm, the actual working lifting height changes to approximately 795–1100 mm because the closed height does not count once installed in a pit.

If your application requires higher lifting ranges than the HW Series provides, you may consider the HD/HT/HF Series, which are designed for extended lifting height requirements or more demanding vertical travel.

3. Platform Size – Tailored to Your Material Handling Needs

The size of the platform is another core customization factor. A properly sized platform improves safety and prevents load overhang or instability.

Questions to clarify:

- What are the dimensions of the materials or pallets being handled?

- Do forklifts or pallet trucks need space for loading?

- Should the platform be extended to accommodate special molds, machinery, or large components?

Typical custom sizes range from compact tables for small parts handling to oversized platforms designed for bulky machinery.

All series—HW, HD, HT, HF, and HY—can be customized in platform length and width to fit unique material handling workflows. Larger platforms may require reinforced scissor arms or upgraded hydraulic cylinders, especially for heavy-duty applications.

4. Installation Method – Pit Installation or Surface Installation

Installation style significantly affects usability, and different product series are ideal for different installation types.

Pit Installation

Pit-mounted lift tables provide a flush working surface. This is especially convenient when using pallet trucks or stackers, as no ramps are needed.

The HW Series is specifically designed for pit installation.

After purchase, we provide detailed pit drawings to ensure accurate construction and perfect table alignment.

For higher lifting heights or more advanced functionality, the HD/HT/HF Series can also be installed in pits, offering more options for varied industries and workflows.

Surface Installation

If you don’t want to build a pit, the HY Series is your ideal option.

This ultra-low stationary lift table comes with a built-in ramp, allowing pallet trucks to roll onto the platform—even without pit installation.

5. Power Supply – Matching Local Electrical Standards

Different regions use different electrical systems.

Confirm voltage and phase early to ensure compatibility.

Common options:

- Single-phase: 110V / 220V

- Three-phase: 380V / 415V / 480V

All series (HW / HD / HT / HF / HY) support custom power configurations.

Conclusion

Customizing a stationary lift table requires careful planning and evaluation of several technical dimensions. The five core factors—load capacity, lifting height, platform size, installation method, and power supply—are essential for designing a safe, efficient, and durable lifting solution.

By also considering operating frequency and environmental conditions, you can ensure that your custom lift table delivers reliable performance and long service life in any industrial setting.

A well-designed lift table not only optimizes workflow efficiency but also significantly enhances workplace safety.