When pallet trucks are the main tool for moving goods, choosing the right lift table design can make a significant difference in efficiency, safety, and workflow speed.

Both U-Shape Low Profile Stationary Lift Tables and E-Shape Low Profile Lift Tables are designed to allow pallet trucks to load pallets directly onto a fixed lifting platform, which then raises the load to an ergonomic working height.

However, while these two designs serve the same basic purpose, they are optimized for different priorities:

- The U-shape focuses on fast, convenient pallet truck access.

- The E-shape focuses on stronger pallet support and improved safety, especially for damaged or weaker pallets.

Understanding these differences will help you choose the best solution for your operation.

Shared Purpose: Pallet Truck Loading to a Fixed Lift Platform

Both U-shape and E-shape low profile lift tables are designed for the same core application:

- A pallet truck carries the load.

- The pallet truck drives onto the lift table.

- The pallet is placed on the platform.

- The pallet truck exits.

- The lift table raises the load to working height.

This setup is ideal for:

- Packing and repacking

- Order picking

- Assembly

- Labeling

- Inspection

- Sorting

- Light production work

In facilities where forklifts are not always practical or allowed, pallet trucks combined with low profile lift tables provide a simple and cost-effective material handling solution.

U-Shape Low Profile Stationary Lift Table: Designed for Speed and Convenience

The U-shape lift table features an open center channel that allows the pallet truck to drive straight through the middle of the platform.

Key Design Features

- U-shaped opening for pallet truck access

- No center support beam

- Quick “drive-in, set down, drive-out” operation

- Optimized for fast loading and unloading

Because there is no central support beam, pallet trucks can pass through the platform without obstruction. This makes the U-shape design extremely convenient for high-frequency pallet handling.

Main Advantages

- Faster pallet truck access

Operators can approach from the front or side and place the pallet quickly. - Simple workflow

No need to carefully align the pallet with support beams. - Ideal for tight schedules

Best for environments where speed matters more than maximum pallet support. - Easy integration

Works well in packing stations, shipping lanes, and production lines.

Limitations

Because the center of the platform is open, the pallet is mainly supported by the two outer sides. For most standard pallets in good condition, this is perfectly safe.

However, damaged, weak, or broken pallets may experience more stress in the middle, which can lead to bending or instability under heavy loads.

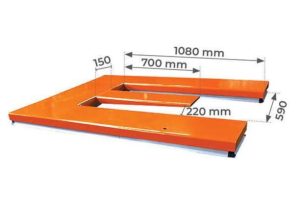

E-Shape Low Profile Lift Table: Built for Stronger Pallet Support

The E-shape lift table has a different structural design. Instead of an open center, it features:

- A central support beam

- Three full support ribs

- A more traditional loading layout

This structure provides full support across the pallet, including the center section.

Key Design Features

- Center beam runs through the middle

- Three strong support ribs

- Even load distribution

- Better support for Euro pallets and industrial pallets

Main Advantages

- Stronger pallet support

The center beam prevents pallets from sagging in the middle. - Safer for damaged pallets

Even cracked or worn pallets remain stable during lifting. - More even load distribution

Weight is spread across the entire platform, improving safety. - Better for heavy-duty use

Ideal for heavier or less predictable pallet conditions.

Limitations

Because of the central beam, pallet truck loading is slightly more traditional:

- The pallet must be carefully positioned

- The truck cannot simply drive through an open center

- Alignment takes more time

While this does not reduce safety, it can slow down the workflow in high-speed environments.

Structural Comparison: U-Shape vs. E-Shape

| Feature | U-Shape Lift Table | E-Shape Lift Table |

| Center Structure | Open U-shaped channel | Central support beam |

| Pallet Support | Two-side support | Three-point full support |

| Pallet Truck Access | Very easy, drive-through | More traditional alignment |

| Best For | Speed & convenience | Safety & load stability |

| Damaged Pallet Handling | Less ideal | Much safer |

| Load Distribution | Moderate | Excellent |

| Workflow Speed | Faster | Slightly slower |

Why the Center Support Beam Matters

Pallets are not always perfect. In real warehouses:

- Pallets get cracked

- Boards loosen

- Bottom decks break

- Load weight becomes uneven

With a U-shape lift table, the center of the pallet has less support. This is usually fine for new, strong pallets, but risky for damaged ones.

The E-shape’s center beam:

- Prevents the middle from sagging

- Reduces bending stress

- Improves safety

- Protects the load

This makes E-shape lift tables especially suitable for:

- Export goods

- Heavy industrial loads

- Reused pallets

- Rough handling environments

Choosing Based on Your Priority

Choose U-Shape If:

- Speed is your top priority

- You use good-quality pallets

- You handle high pallet volumes

- You want fast pallet truck entry/exit

- Your workflow demands quick turnover

Typical environments:

- Packing stations

- Shipping areas

- E-commerce fulfillment

- Light manufacturing

Pallet Truck vs. E-shape Low Profile Lift Table – Dimension Matching Table

| Pallet Truck Parameter | Corresponding Lift Table Parameter | Matching Requirement |

|---|---|---|

| Fork Overall Width | E-opening Total Width | Fork overall width < E-shape opening total width |

| Single Fork Width | Single Slot Width | Single fork width < single slot width |

| Fork Thickness | Minimum Lowered Height | Fork thickness < minimum lowered height |

| Inner Fork Distance | Center Beam / Middle Structure Width | Center structure width < inner fork distance |

| Fork Length | E-opening Depth | Fork length ≥ 70–80% of E-opening depth |

Choose E-Shape If:

- Safety is your top priority

- You often use damaged pallets

- You handle heavy loads

- You need strong center support

- You want maximum stability

Typical environments:

- Industrial production

- Heavy goods handling

- Export packing

- Warehouses with reused pallets

Pallet Truck vs. U-shape Low Profile Lift Table – Dimension Matching Table

| Pallet Truck Parameter | Corresponding Lift Table Parameter | Matching Requirement |

|---|---|---|

| Fork Overall Width | U-opening Inner Width | Fork overall width ≤ U-shape opening inner width |

| Single Fork Width | Platform Side Clearance | Single fork width ≤ available side clearance |

| Fork Thickness | Minimum Lowered Height | Fork thickness < minimum lowered height |

| Fork Inner Distance | U-opening Inner Clearance | U-opening inner clearance ≤ inner fork distance |

| Fork Length | U-opening Depth | Fork length ≥ 70–80% of U-opening depth |

Both Designs Improve Ergonomics

No matter which design you choose, both lift tables offer the same ergonomic benefits:

- Reduced bending

- Less strain on the back

- Safer working posture

- Improved productivity

- Lower injury risk

By raising pallets to a comfortable height, workers can handle goods more efficiently and safely.

Installation and Operation Considerations

Both U-shape and E-shape lift tables:

- Are stationary (fixed position)

- Work with pallet trucks

- Require proper floor placement

- Need power connection (hydraulic system)

- Offer safety features such as overload protection

Before choosing, always check:

- Pallet truck width

- Pallet size

- Load weight

- Floor space

- Daily usage frequency

Final Thoughts

Both U-Shape and E-Shape Low Profile Lift Tables are excellent solutions for pallet truck loading at fixed workstations. The right choice depends on what matters most in your operation:

- Speed and convenience?→ Choose U-Shape

- Safety and full pallet support?→ Choose E-Shape

If your pallets are usually in good condition and your operation is fast-paced, the U-shape design will keep things moving smoothly.

If your pallets are often damaged, heavily loaded, or reused, the E-shape design provides stronger support and better long-term safety.

Either way, both designs will improve ergonomics, efficiency, and material handling performance.