Introduction of Electric Self-propelled Lift Table

Electric Self-propelled Lift Table features a proven Curtis controller and Hall accelerator to provide effortless lifting, lowering and movement of heavy loads. A push of a button will raise and lower the platform, and a twist style throttle with reverse powers the front drive wheels. Battery operated scissor lift Table has a 24V DC battery operated unit features an on-board battery charger and maintenance free batteries. Meets EN 1570 norm and ANSI/ASME safety standards.

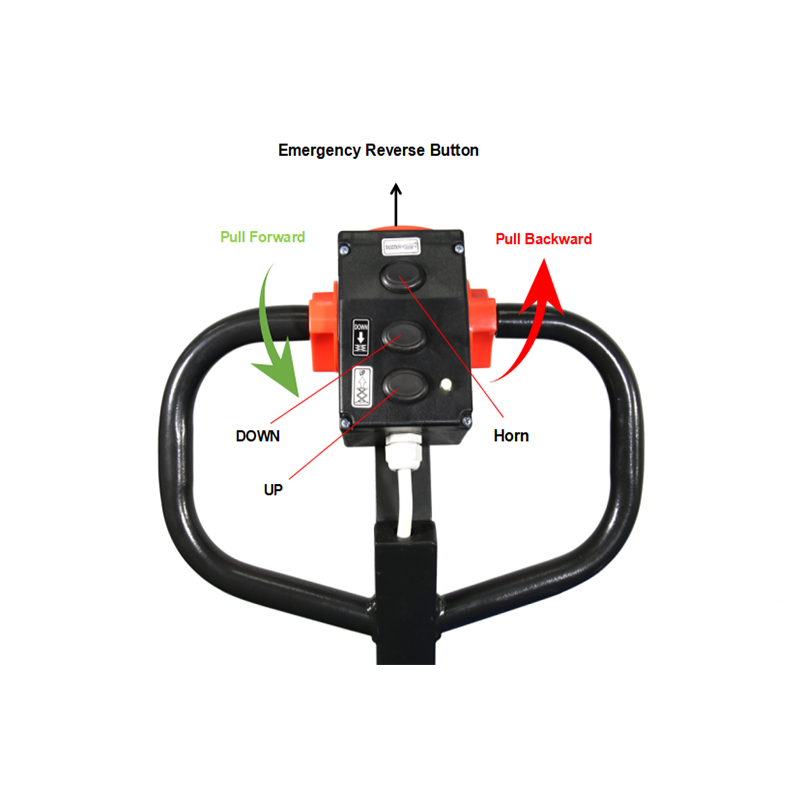

This series full electric lift table is self-propelled and electric lifting, Emergency reverse button for maximum safety in emergency situations. Uniquely designed tool storage box helps store tools.

ESM series self-propelled electric lift table has differnent models like ESF50, ESF50D, ESM50, ESM50D, ESM80 and ESM91D, they are different from the handle and the scissor, ESF50, ESM50 and ESM80 are single scissor lift table and ESF50D, ESM50D, ESM91D are doule scissor lift table. ESF50 and ESF50D are fixed handle and the others are middle steering handle.

Specification of Electric Self-propelled Lift Table

| i-Lift No. | 1310201 | 1310202 | 1310203 | 1310204 | 1310205 | 1310206 | |

| Model | ESF50 | ESF50D | ESM50 | ESM50D | ESM80 | ESM91D | |

| Type | Fixed Handle | Middle Steering Handle | |||||

| Capacity | kg(lb.) | 500(1100) | 910(2000) | ||||

| Table size(L*W) | mm(in.) | 1020*610(40.2*24) | |||||

| Table height(Max./Min.) | mm(in.) | 1000/460(40/18) | 1720/460(68/18) | 1000/460(40/18) | 1720/470(68/18) | 1075/460(42/18) | 1850/520(73/20.5) |

| Lifting Cycle | 55 | 40 | 55 | 40 | 45 | 40 | |

| Wheel Dia. | mm(in.) | 200(8) | |||||

| Lifting/Lowering Time | second | 15/15 | |||||

| Overall size | mm(in.) | 1200*670*1030(47.2*26.4*40.6) | 1400*670*1170(55*26.4*46.1) | ||||

| Net Weight | kg(lb.) | 214(470.8) | 220(484) | 220(484) | 235(517) | 240(528) | 250(550) |

Advantages of Electric Self-Propelled Lift Table

Video Show:

1. Self-Propelled Driving System

Equipped with an electric drive motor for effortless movement

No manual pushing required, reducing labor intensity

Improves maneuverability in tight operational spaces

2. Adjustable Scissor Lift Platform

Provides stable vertical lifting

Smooth height adjustment for ergonomic working

Ideal for assembly, positioning, loading, and unloading tasks

3. Enhanced Productivity & Efficiency

Allows one operator to both drive and lift the load

Speeds up internal logistics and material transportation

Reduces downtime during production

4. Improved Workplace Safety

Minimizes the risk of musculoskeletal injuries

Stable platform prevents load shifting

Fitted with safety braking systems and overload protection

5. High-Performance Battery & Low Maintenance

Long-lasting battery supports continuous operation

Low energy consumption and minimal maintenance costs

Suitable for daily industrial use

Application of Electric Self-Propelled Lift Tables

Self-propelled lift tables are widely adopted in environments requiring frequent load transportation and height adjustment:

Manufacturing plants – moving components, assembly support

Warehousing & distribution centers – order picking, goods handling

Automotive industry – parts lifting, assembly lines

Packaging & printing facilities – transferring large materials

Logistics companies – loading/unloading tasks

Maintenance departments – equipment servicing, repair support

Their ability to function as both a mobile lifting table and a powered transport cart makes them extremely versatile for modern industrial operations.

Attention and Maintenance:

- Charge the charger for more than 12 hours when it is used for the first time. Check whether the electrical connectors of the electric lifting platform are loose when charging. If the electric connector of the electric lifting platform is loose, it should be tightened and then recharged.

- Check the parts of the electric lifting platform for deformation and bending;

- Check if the brakes of the electric lifting platform are malfunctioning and the wear of the wheels of the electric lifting platform;

- Check the hydraulic system of the electric lifting platform for oil leakage;

- Check the high-pressure fuel pipe of the electric lifting platform for damage. If is damaged, it should be replaced in time. Or the rupture in using will cause a major danger;

- Fill the friction surfaces with lubricating oil before using the electric lifting platform every day;

- Recharge in time after using the electric lifting platform every day;

- If the electric lifting table is faulty, it should be repaired before use;

- Replace the hydraulic oil of the mobile table every 12 months, and select the correct hydraulic oil according to the climatic conditions of different regions.