Forklift fork extensions are practical and cost-effective attachments that allow standard forklift forks to lift longer, bulkier, or awkward loads. For procurement professionals, however, choosing the right extension is not as simple as selecting a length from a catalog. Incorrect sizing or specifications can compromise safety, reduce lifting capacity, and damage equipment.

This guide explains what procurement teams must check, which measurements to provide to suppliers, and which safety rules should always be followed to ensure you purchase the correct forklift fork extensions for your operation.

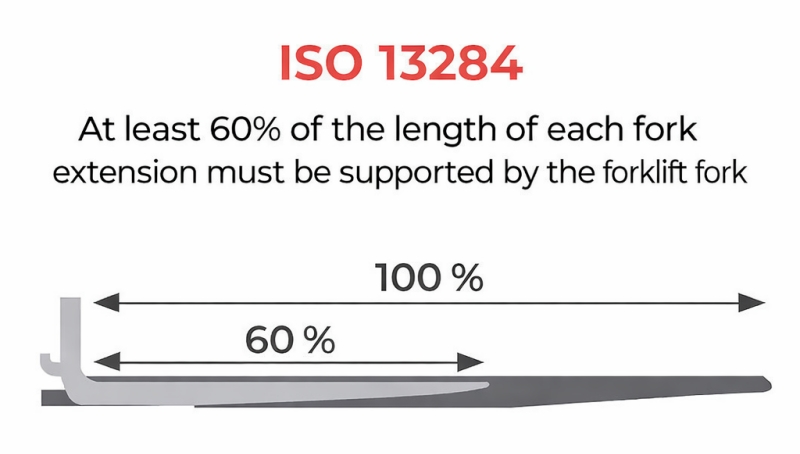

1. Understand the Safety Rule: At Least 60% of the Extension Must Rest on the Fork

Most professional material-handling guidelines emphasize one critical safety requirement:

👉 At least 60% of the forklift fork extension must be supported by the original fork.

This means the extension must not extend too far beyond the forklift’s existing fork length.

For example:

- If your forklift forks are 1200 mm, then the extension must have at least 720 mm (60%)of its length resting on the original fork.

If the unsupported portion is too long, it causes:

- unstable load support

- reduced forklift lifting capacity

- excessive bending stress at the extension tip

- increased risk of load dropping or tip-forward accidents

This stability rule is the foundation of all sizing decisions for forklift fork extensions.

2. Measure the Exact Fork Dimensions (Width, Thickness, Length)

To ensure a precise fit, procurement staff must provide the supplier with accurate fork measurements. Forklift forks differ across models and capacity levels, so assumptions can lead to dangerous mismatches.

a. Fork Width (A Critical Fit Dimension)

Fork extensions must slide over the fork with minimal side-to-side movement.

- Typical widths: 100 mm, 125 mm, 150 mm

- Too wide = unsafe looseness

- Too narrow = the extension cannot be installed

Provide your supplier with:

✔ exact fork width measured from outer edge to outer edge

b. Fork Thickness / Height

This is the vertical height of the fork blade. The inner height of the extension must be slightly larger for smooth installation.

- Typical thickness: 40–60 mm

Provide:

✔ fork thickness measured from the bottom to top surface

c. Fork Length (Usable Length Only)

Measure from the heel to the tip.

This determines whether the extension can maintain the minimum 60% support requirement.

Provide:

✔ usable fork length (not including the vertical heel)

3. Check the Forklift Model and Capacity

Not all forklifts can safely use every type of extension. A supplier needs your forklift model to confirm:

- carriage type (Class II, III, or IV)

- fork size compatibility

- original load capacity

- load center distance

- any manufacturer restrictions

Fork extensions reduce the effective lifting capacity because they shift the load center forward. Some forklift models are more tolerant than others, and sellers will apply this information when giving recommendations.

Always provide:

✔ forklift brand

✔ model

✔ rated lifting capacity

4. Confirm the Load Type and Maximum Load Weight

Fork extensions change how the forklift handles weight. The longer the extension, the more the load center shifts outward, reducing lifting stability.

Procurement must specify:

a. Maximum load weight

Suppliers need this to determine whether the extension’s structural design (reinforcement, steel thickness) is suitable.

b. Type of load

Different loads may require different extension designs:

- Long pallets → standard box extensions

- Pipes / tubes → round-bottom extensions

- Wide, flat objects → reinforced heavy-duty extensions

Provide:

✔ maximum weight per load

✔ type and dimensions of load being lifted

5. What Procurement Should Tell the Seller (Checklist)

Before requesting a quotation, provide the seller with all necessary technical information:

✔ Fork length

✔ Fork width

✔ Fork thickness

✔ Desired extension length

✔ Maximum load weight

✔ Type of materials being lifted

✔ Forklift model + rated capacity

This ensures fast matching with the correct extension type.

Conclusion

Selecting the right forklift fork extensions requires more than choosing a length. Procurement teams must provide accurate fork measurements, forklift specifications, load details, and usage patterns to the supplier. Sellers, in turn, must verify safety rules, perform compatibility checks, and ensure the extension’s build quality meets the application demands.

By following the guidelines above, buyers can confidently purchase extensions that are safe, durable, compatible, and optimized for their operational needs.