Industrial workplaces, warehouses, and manufacturing facilities are constantly looking for efficient ways to move and position heavy loads. If you’re in the market for a mobile electric lift table cart, such as the ES Series electric scissor lift table cart from i-Lift Equipment, this detailed buying guide will help you make an informed decision before you invest.

Electric lift table carts have become essential tools in modern material handling. They improve productivity, reduce physical strain, and enhance workplace ergonomics. But with numerous models and features available, choosing the right one isn’t always straightforward. Below, we break down the key factors to consider — from load capacity to maintenance — so you can select the right unit for your needs.

What Is an Electric Lift Table Cart?

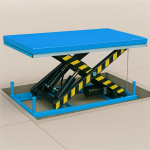

An electric lift table cart is a battery-powered mobile platform designed to lift, lower, and transport heavy loads over short distances. These carts combine the benefits of a traditional lift table with improved mobility and automated lifting functions, making them ideal for industrial, commercial, and even office settings.

Unlike manual lift tables that require physical effort, electric models use a battery and motor to power the lifting mechanism. With a push of a button, operators can raise or lower loads safely and effortlessly. This convenience makes electric lift tables a smart choice for high-frequency material handling tasks.

1. Load Capacity: Match the Cart to Your Weight Needs

One of the most crucial aspects to consider is the maximum load capacity of the electric lift table cart.

- The ES Series electric lift table carts offer capacities ranging from 300 kg (660 lb) up to 1000 kg (2200 lb) depending on the model (e.g., ES30, ES50, ES75, ES100, and their “D” double-scissor variants).

When selecting a lift table:

- Add up the weight of the load plus any accessories or packagingyou might place on the platform.

- Choose a cart with a slightly higher capacitythan your maximum expected workload to ensure durability and safety.

2. Lift Height: Know Your Vertical Requirements

Another essential factor is the maximum and minimum lift height.

- Certain ES Series models, like the ES100 or ES80D, reach planned heights suitable for loading onto racks or aligning with conveyor systems.

Tips:

- Make sure the lift table can reach workbench height or higherif your process requires stacking or loading onto other equipment.

- For ergonomic workstations or assembly lines, consider models with a wide height range.

3. Battery & Power: Choose Reliable Performance

Electric lift tables typically run on a 12V battery system with onboard chargers.

- The ES Series uses high-quality batteries(e.g., 54 Ah for single scissor models, 80 Ah for double scissor models) and comes with an onboard automatic charger for convenience.

What to consider:

- Battery life and cycle durability(number of charges).

- Charger compatibility with your facility(110V/220V).

- Ease of replacement and maintenance.

Opting for a model with a more powerful battery can mean smoother performance and longer runtime between charges — a key advantage for high-usage environments.

4. Mobility & Maneuverability

Mobility is what sets electric lift table carts apart from stationary lift tables.

- ES Series carts include swivel castors with brakesto improve handling and safety on the floor.

When evaluating mobility:

- Consider wheel type and brake design: stronger braking systems and good wheels ensure safer movement over different floor types.

- Check whether the cart is easy to steer in narrow aislesand if it turns smoothly without heavy effort.

5. Safety Features

Safety should be a priority for any material handling equipment.

Look for features such as:

- Emergency lowering valvesto safely lower loads if the power fails.

- Brake systems on wheelsthat lock the cart in place during loading/unloading.

- Stable and robust frame constructionto prevent tipping.

- Clear control handlesthat are simple to operate.

Enhanced safety features not only protect operators but also reduce liability risks within your workplace.

6. Maintenance & Longevity

All industrial equipment benefits from regular maintenance — electric lift tables are no exception.

Here are a few maintenance considerations:

- Inspect connections and battery terminals frequently.

- Regularly check the brakes and wheels for wear.

- Ensure hydraulic fluid levels are adequate and free of leaks.

Tip: keeping a maintenance schedule helps prolong service life and prevents costly downtime.

7. Budget & Value

Finally, think about total cost of ownership.

- Electric models generally cost more upfront compared to manual units, but they offer significant long-term efficiency and ergonomic benefits.

- If your workplace uses lift tables all day, every day, investing in a robust electric model is often worth the price.

Final Thoughts

An electric lift table cart is a powerful tool for modern material handling. By focusing on capacity, lift height, power system, mobility, safety, and maintenance, you’ll make a smart purchase decision that benefits productivity and worker wellness.

The ES Series Electric Lift Table Cart from i-Lift Equipment strikes a great balance of strength, versatility, and reliability — whether you’re lifting goods in a warehouse, moving tools in a workshop, or boosting ergonomics on a production line.