Description of QET-P Electric Pallet Truck

The QET-P Series designed to be used with high efficiency even during their multi-shift operation. The configuration of the trucks allows you to get more powerful and productive units thanks to its increased speed and different options of batteries,including lithium solutions,

▲Sideway battery replacement allows customers to use the truck with multi-shift operation and not towaste time on complicated procedure of battery replacement through the top. With help of specially designed trolly, the batteries can be replaced fast and effortlessly.

▲The option of PIN-Code panel access, can significantly simplify the procedure of access limitation for the procedure of access limitation for the fleet which may be used by more than one operator.

▲The trucks can be equipped with the option of the system of fast refilling of distilled water in lead-acid batteries.

▲The model Range can be equipped with lithium batteries. The use of lithium solution will allow you to enjoy benifits of lithium technology such as fast charging, opportunit charging,

maintenance free, environmental-friendly, smart diagnosis of battery status, lower cost of total ownership with long service life.

▲The model range can be equipped with the option of Electric power steering (EPS) which delivers precise and fast control for the position of steering wheel and has a high level of reliability as well as safety according to official standards.

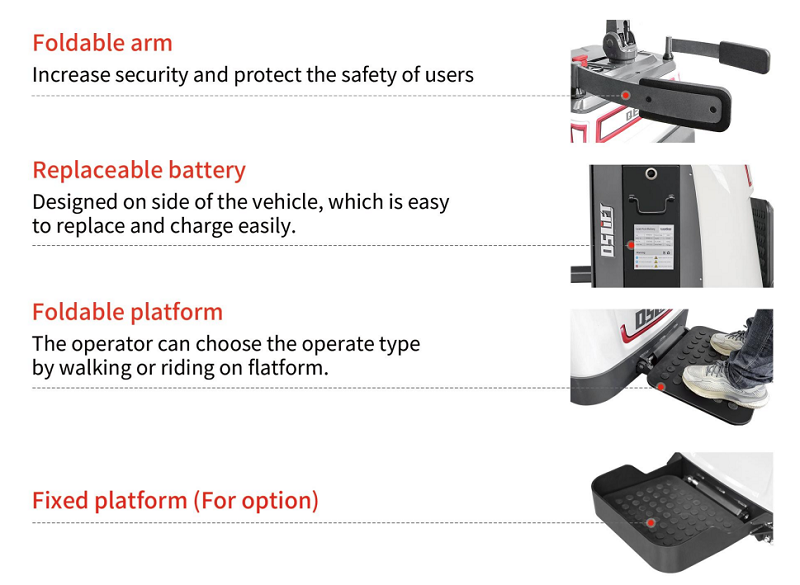

Details of QET-P Electric Pallet Truck

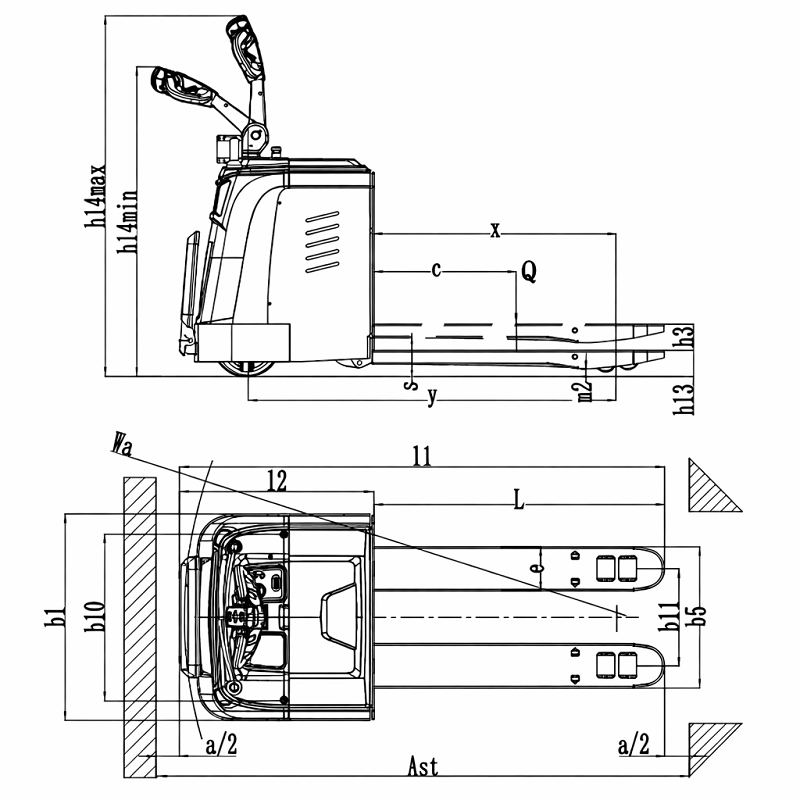

Specification of QET-P Electric Pallet Truck

| Characteristics | 1.1 | Model | QET20P | QET25P | QET30P | |

| 1.2 | Drive type | Battery | ||||

| 1.3 | Operator type | Pedestrian/Stand | ||||

| 1.4 | Capacity | Q(kg) | 2000 | 2500 | 3000 | |

| 1.5 | Load centre distance | c(mm) | 600 | 600 | 600 | |

| Weight | 2.1 | Service Weight / Exl. battery | kg | 500 | 520 | 520 |

| Wheel | 3.1 | Tires | Polyurethane ( PU ) | |||

| 3.2 | Size of load roller,Number | Φ80×70, 4 | ||||

| 3.3 | Size of Balance roller, Number | Φ115×55, 2 | ||||

| 3.4 | Size of Steering wheel | Φ250×80 | ||||

| 3.5 | Tread, Rear | b11(mm) | 625 | |||

| 3.6 | Tread, Front | Y(mm) | 1500 | |||

| Size | 4.1 | Lifting Height | h3(mm) | 120 | 120 | 120 |

| 4.2 | Height of tiller in Drive position/Max. | h1(mm) | 1450 | |||

| 4.3 | Max. Height of Fork | h4(mm) | 205 | |||

| 4.2 | Min. Height of Fork | h13(mm) | 85 | |||

| 4.3 | Overall Length | l1(mm) | 1930 | |||

| 4.4 | Overall Width | b1(mm) | 820 | |||

| 4.5 | Fork Dimensions | S/e/l(mm) | 50/176/1150 | |||

| 4.6 | Width across forks | b5(mm) | 560/685 | |||

| 4.7 | Ground clearance, centre of wheelbase | m2(mm) | 30 | |||

| 4.8 | Aisle width for pallets 1000x1200 Crossways | Ast(mm) | 2130 | |||

| 4.9 | Aisle width for pallets 800x1200 Lengthways | Ast(mm) | 2180 | |||

| 4.1 | Turning Radius | Wa(mm) | 1750 | |||

| Performance | 5.1 | Travel Speed,Laden/unladen | Km/h | 5.5/5.8 | ||

| 5.2 | Lift Speed,Laden/unladen | m/s | 0.04/0.05 | |||

| 5.3 | lowering Speed,Laden/unladen | m/s | 0.06/0.05 | |||

| 5.4 | Gradeability,Laden/unladen | % | 8/20 | |||

| 5.5 | Service Brake | Electromagnetic | ||||

| Electric engine | 6.1 | Drive motor rating | kW | 1.5/2.2(AC) | ||

| 6.2 | Lifting motor rating | kW | 2.2 | |||

| 6.3 | Battery capacity | V/Ah | Lead-acid 24/210 | Lead-acid 24/210 | Lead-acid 24/270 | |

| Lithium 24/160 | Lithium 24/160 | Lithium 24/200 | ||||

| 6.4 | Battery weight | Kg | Lead acid 200/260 | |||

| Lithium 82/85 | ||||||

| 6.5 | Type of Steering | Mechanical steering/ EPS | ||||

| Others | 7.1 | Type of drive control | AC speed control | |||

| 7.2 | Sound level at driver's ear acc. to DIN12053 | dB(A) | <70 | |||

Main Feature of EPT Series Electric Pallet Truck

High strength chassis design

The high strength chassis and compact design ensure the long life and flexibility. Specifically supported by its perfect metal welding and bending technology, and metal toughness as well.

Variety battery capacity available

By pairing battery volumes and its chargers to match various work time demands.

Security and stability

The hydraulic lifting system of this vehicle adopts the design without oil pipe, which greatly improves the reliability of the hydraulic system and reduces the risk of oil leakage of the joint or oil pipe.

Intelligent control system

Equipped with CAN-BUS technology, automatically monitoring the status of the truck, and fault diagnosis.